Skyview has partnered with TechnipFMC since 2015 to ensure compliance with rigorous onsite health and safety requirements, reduce operational downtime and to facilitate safe working conditions for engineers at their Evanton Spoolbase. Spoolbase activity is unique within the pipeline construction industry as it is a combination of onshore and offshore pipeline construction.

About TechnipFMC

TechnipFMC is an industry leader in subsea, onshore, offshore, and surface technologies. Operating four strategically located spoolbases around the world based in Evanton, UK; Orkanger, Norway; Mobile, Alabama, USA; and Dande, Angola, TechnipFMC aims to enhance the performance of the global energy industry.

TechnipFMC’s onshore welding operations and non-destructive testing are off the critical path, allowing for high quality weld production. While their reeled pipeline technology provides a cost-efficient and faster installation process compared to other methods.

The Challenge

The reeling process begins with spooling the pipeline onto the vessel. A pipestalk is pulled from the spoolbase onto the vessel and then plastically bent in a controlled manner around the reel. The process continues until the second end of the pipestalk reaches the end of spoolbase causeway. The end of that pipestalk is then welded to the start of the next pipestalk. Non-destructive examination of the weld is performed and the field joint coating applied. This process is repeated until the required length of pipeline has been spooled onto the vessel reel(s).

Engineering teams at Evanton Spoolbase then load offshore undersea cables onto massive drums, which are then loaded onto cable laying vessels.

The impact that extreme weather would have on such complex processes could be disastrous if not carefully planned for. With lightning having the potential to strike from 10 miles away, any unplanned for lightning strikes could prove catastrophic for the spooling process, not to mention the operational challenges and financial risks that weather downtime poses for offshore operators.

Our Solution

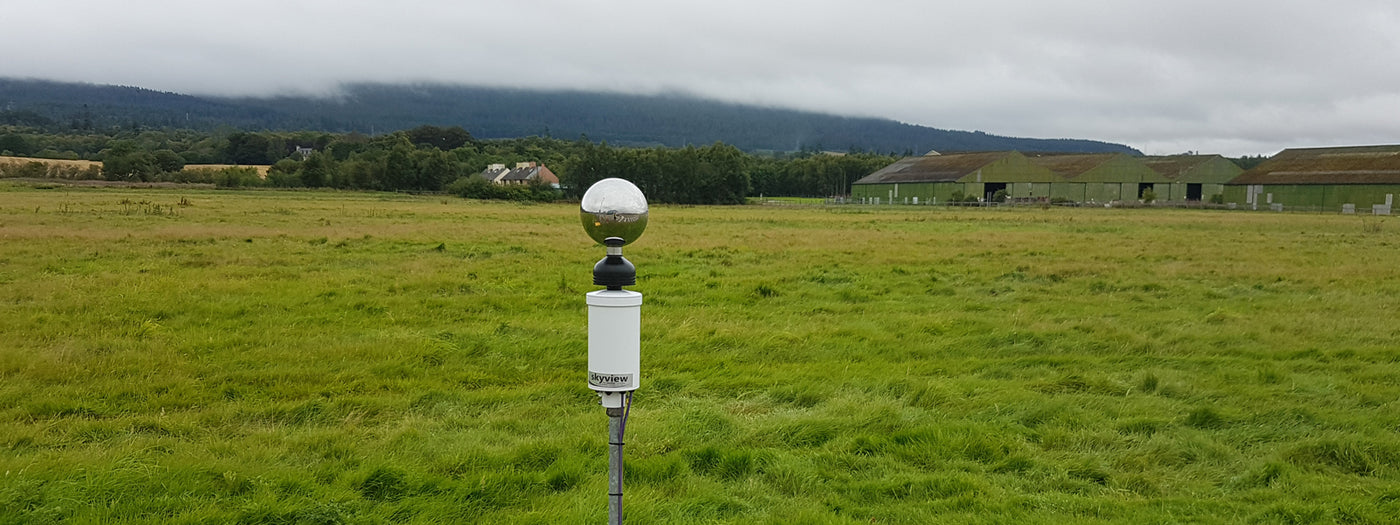

With over 30 years’ experience in offshore weather monitoring solutions, our expert engineers perfectly understand the risks and requirements associated with such a complex project. After close consultation with the Evanton team, a bespoke lightning detection system was designed and installed, complete with traffic light display unit. Green, amber and red visual alerts provide staff with an easy to use guide as to the status of the lightning system. A specially incorporated blue fault light means the weather equipment requires supervisor attention. An audible buzzer brings immediate attention to lightning safety whether site staff are looking at the display unit or not.

Technip’s lightning detection and alert system is a solid state system. With no moving parts, the system provides improved accuracy and reliability when compared with the performance of a traditional electric field mill.

The lightning detector is configured by PC software, enabling Technip to specify the range of detection that activates the different alert levels. When lightning is detected, or if the presence of electrical charge in the atmosphere indicates a lightning strike is likely, the unit will provide gatehouse staff with visual and audible warnings to take appropriate action to ensure the safety of all on site. Further remote lightning alarm indication units located at various crucial work points mimic the master indicator installed in the gatehouse to ensure that the real time alerts are visible to the whole team at various working points and that no time is wasted in getting all staff to safety.